CANTEX DRILLS ANOTHER OUTSTANDING INTERSECTION OF 9 METRES OF 34.08% LEAD-ZINC AND 96 G/T SILVER AT ITS NORTH RACKLA PROJECT IN THE YUKON

KELOWNA, B.C., Jan. 20, 2025 /PRNewswire/ — Cantex Mine Development Corp. (TSXV: CD) (OTCQB: CTXDF) (the “Company”) is pleased to provide an update on its 100-percent-owned 14,077 hectare North Rackla claim block in the Yukon, Canada.

Dr. Charles Fipke reports

Main Zone Drilling

Cantex is pleased to receive the base metal results from the remaining holes at its 2024 drill program at North Rackla.

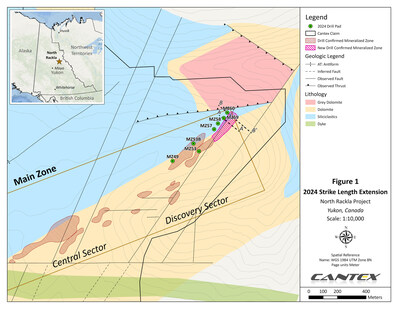

The drilling at the Massive Sulphide Zone focused on the Discovery Sector and successfully extended the strike length of the Main Zone to 2.65 kilometres, an increase of 300 metres this season (Figures 1 to 3). The mineralization remains open both along strike and to depth.

Results from twenty-six holes completed on the Discovery Sector of the Main Zone have been received and these results are presented in Table 1 below.

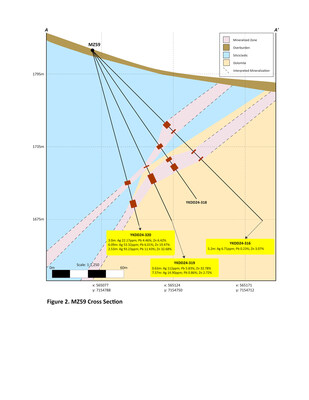

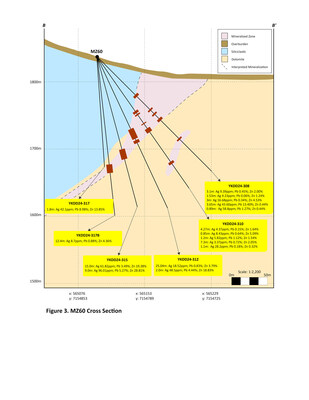

Highlights from these holes include a 9 metre interval of 34.08% combined lead-zinc and 96 g/t silver within a broader interval of 15 metres of 22.87% combined lead-zinc and 62 g/t silver in hole YKDD24-315. Hole YKDD24-312 intersected a 2 metre interval of 23.27% lead-zinc and 48 g/t silver within a lengthy 25.04 metre intercept of 4.62% combined lead-zinc and 18 g/t silver.

Significantly, both of these holes were drilled from Pad MZ60, the furthest NE pad from which drilling has been undertaken (see Figure 3).

As presented in Table 1, the drilling in the northeastern portion of the Main Zone contains elevated copper values suggesting that this could be the central feeder zone of the mineralization. For example, hole YKDD24-313, drilled from pad MZ58 intersected a zone of mineralization containing 0.68% copper. If in fact this area near the northeast end of our drilling (see Figure 1) is the centre of the deposit, then the strike length could possibly be almost twice the current drill-defined length. The deposit also remains open at depth where 23.67 metres of sulphides including massive sulphides were intersected at 700 metres depth (see news release dated December 17, 2020).

Table 1. Significant drill results from the Discovery Sector

|

Pad |

Dip |

Azimuth |

Hole |

From |

To |

Interval |

Silver |

Lead |

Zinc |

Lead + Zinc |

Copper |

|

(m) |

(m) |

(m) |

g/t |

( %) |

( %) |

( %) |

( %) |

||||

|

MZ49 |

-45 |

145 |

YKDD24-327 |

92.00 |

95.00 |

3.00 |

9.67 |

1.08 |

2.46 |

3.54 |

0.01 |

|

120.60 |

125.60 |

5.00 |

50.33 |

5.56 |

8.55 |

14.11 |

0.06 |

||||

|

159.50 |

161.20 |

1.70 |

26.36 |

6.51 |

6.63 |

13.14 |

0.04 |

||||

|

MZ53 |

-65 |

145 |

YKDD24-330 |

19.00 |

25.50 |

6.50 |

9.84 |

2.89 |

2.44 |

5.33 |

0.01 |

|

41.30 |

42.60 |

1.30 |

22.88 |

0.37 |

0.67 |

1.03 |

0.25 |

||||

|

MZ53B |

-75 |

130 |

YKDD24-307 |

92.40 |

93.70 |

1.30 |

18.02 |

1.04 |

1.10 |

2.14 |

0.07 |

|

98.30 |

106.45 |

8.15 |

17.91 |

2.13 |

5.97 |

8.11 |

0.03 |

||||

|

109.50 |

110.55 |

1.05 |

38.10 |

7.03 |

9.76 |

16.79 |

0.03 |

||||

|

128.10 |

131.18 |

3.08 |

37.07 |

8.45 |

6.88 |

15.33 |

0.02 |

||||

|

137.28 |

138.65 |

1.37 |

16.85 |

4.24 |

1.89 |

6.13 |

0.02 |

||||

|

161.71 |

162.27 |

0.56 |

13.35 |

2.61 |

4.13 |

6.74 |

0.01 |

||||

|

-45 |

145 |

YKDD24-329 |

57.93 |

58.90 |

0.97 |

5.47 |

0.27 |

2.31 |

2.58 |

0.00 |

|

|

97.42 |

107.78 |

10.36 |

9.39 |

0.88 |

3.39 |

4.27 |

0.02 |

||||

|

112.32 |

113.16 |

0.84 |

7.97 |

0.61 |

2.33 |

2.94 |

0.01 |

||||

|

-55 |

145 |

YKDD24-331 |

104.00 |

106.00 |

2.00 |

3.28 |

0.67 |

1.54 |

2.21 |

0.01 |

|

|

MZ57 |

-45 |

130 |

YKDD24-321 |

93.00 |

94.75 |

1.75 |

4.00 |

0.91 |

2.17 |

3.08 |

0.01 |

|

127.50 |

128.00 |

0.50 |

4.17 |

0.67 |

0.94 |

1.61 |

0.03 |

||||

|

-55 |

130 |

YKDD24-323 |

91.35 |

99.53 |

8.18 |

34.35 |

12.95 |

0.93 |

13.88 |

0.07 |

|

|

Including |

96.50 |

99.53 |

3.03 |

59.79 |

25.07 |

0.67 |

25.73 |

0.01 |

|||

|

-65 |

130 |

YKDD24-324 |

92.75 |

93.75 |

1.00 |

1.67 |

0.18 |

2.25 |

2.43 |

0.01 |

|

|

96.65 |

101.4 |

4.75 |

11.51 |

2.66 |

1.31 |

3.97 |

0.07 |

||||

|

-75 |

130 |

YKDD24-325 |

108.00 |

110.50 |

2.50 |

14.07 |

3.11 |

3.37 |

6.49 |

0.03 |

|

|

MZ58

|

-45 |

130 |

YKDD24-309 |

92.00 |

93.02 |

1.02 |

18.00 |

0.35 |

2.54 |

2.89 |

0.32 |

|

98.00 |

98.50 |

0.50 |

8.14 |

2.96 |

0.03 |

2.99 |

0.00 |

||||

|

102.50 |

106.50 |

4.00 |

6.46 |

0.26 |

4.31 |

4.56 |

0.05 |

||||

|

139.00 |

140.80 |

1.80 |

30.78 |

2.39 |

1.53 |

3.92 |

0.14 |

||||

|

-55 |

130 |

YKDD24-311 |

98.60 |

108.60 |

10.00 |

13.10 |

2.88 |

1.55 |

4.43 |

0.02 |

|

|

150.45 |

151.35 |

0.90 |

12.40 |

2.48 |

10.10 |

12.58 |

0.05 |

||||

|

161.43 |

161.97 |

0.54 |

40.50 |

11.55 |

2.30 |

13.85 |

0.12 |

||||

|

-65 |

130 |

YKDD24-313 |

110.10 |

111.70 |

1.60 |

4.12 |

0.08 |

1.71 |

1.79 |

0.02 |

|

|

155.92 |

156.80 |

0.88 |

75.40 |

0.41 |

0.38 |

0.79 |

0.68 |

||||

|

-75 |

130 |

YKDD24-314 |

119.85 |

123.00 |

3.15 |

22.60 |

3.62 |

7.06 |

10.67 |

0.03 |

|

|

MZ59 |

-45 |

130 |

YKDD24-316 |

85.80 |

91.00 |

5.20 |

6.71 |

0.23 |

3.07 |

3.30 |

0.05 |

|

95.30 |

96.30 |

1.00 |

12.2 |

0.32 |

5.25 |

5.57 |

0.03 |

||||

|

118.65 |

120.35 |

1.70 |

8.22 |

0.34 |

1.47 |

1.81 |

0.04 |

||||

|

-55 |

130 |

YKDD24-318 |

97.20 |

100.12 |

2.92 |

8.38 |

1.67 |

4.07 |

5.73 |

0.04 |

|

|

117.27 |

122.00 |

4.73 |

11.49 |

2.52 |

2.60 |

5.12 |

0.03 |

||||

|

-65 |

130 |

YKDD24-319 |

106.21 |

106.84 |

0.63 |

112.00 |

5.83 |

32.78 |

38.61 |

0.06 |

|

|

113.97 |

121.54 |

7.57 |

14.90 |

0.86 |

2.72 |

3.58 |

0.16 |

||||

|

-75 |

130 |

YKDD24-320 |

113.5 |

116.5 |

3.00 |

22.17 |

4.46 |

6.42 |

10.88 |

0.02 |

|

|

129.91 |

136.00 |

6.09 |

53.32 |

6.01 |

19.47 |

25.48 |

0.03 |

||||

|

Including |

131.00 |

133.53 |

2.53 |

93.23 |

11.43 |

32.68 |

44.11 |

0.04 |

|||

|

MZ60 |

-45 |

130 |

YKDD24-308 |

82.40 |

85.50 |

3.10 |

9.39 |

0.45 |

2.00 |

2.45 |

0.08 |

|

113.77 |

115.30 |

1.53 |

4.23 |

0.06 |

1.24 |

1.29 |

0.00 |

||||

|

121.00 |

124.00 |

3.00 |

12.68 |

0.34 |

4.53 |

4.87 |

0.02 |

||||

|

132.05 |

135.70 |

3.65 |

43.60 |

13.40 |

5.89 |

19.29 |

0.02 |

||||

|

175.05 |

175.94 |

0.89 |

58.80 |

1.26 |

0.44 |

1.70 |

0.50 |

||||

|

-55 |

130 |

YKDD24-310 |

96.90 |

101.17 |

4.27 |

4.37 |

0.15 |

1.64 |

1.79 |

0.04 |

|

|

103.15 |

104.00 |

0.85 |

8.43 |

0.64 |

5.09 |

5.73 |

0.02 |

||||

|

119.00 |

120.20 |

1.20 |

5.82 |

1.12 |

1.54 |

2.66 |

0.02 |

||||

|

128.00 |

135.30 |

7.30 |

3.37 |

0.72 |

2.05 |

2.77 |

0.01 |

||||

|

191.00 |

192.10 |

1.10 |

28.20 |

0.18 |

0.32 |

0.50 |

0.39 |

||||

|

-65 |

130 |

YKDD24-312 |

117.50 |

142.54 |

25.04 |

18.52 |

0.83 |

3.79 |

4.62 |

0.08 |

|

|

Including |

128.00 |

130.00 |

2.00 |

48.50 |

4.44 |

18.83 |

23.27 |

0.03 |

|||

|

-75 |

130 |

YKDD24-315 |

141.00 |

156.00 |

15.00 |

61.82 |

3.49 |

19.38 |

22.87 |

0.13 |

|

|

Including |

141.00 |

150.00 |

9.00 |

96.01 |

5.27 |

28.81 |

34.08 |

0.20 |

|||

|

-85 |

130 |

YKDD24-317* |

161.70 |

163.50 |

1.80 |

42.10 |

8.98 |

13.85 |

22.83 |

0.03 |

|

|

-85 |

130 |

YKDD24-317B |

161.80 |

174.20 |

12.40 |

8.70 |

0.88 |

4.36 |

5.24 |

0.03 |

|

|

-45 |

99 |

YKDD24-322 |

137.30 |

148.10 |

10.80 |

12.94 |

2.67 |

2.77 |

5.44 |

0.08 |

|

|

250.50 |

251.00 |

0.50 |

9.52 |

2.39 |

0.27 |

2.66 |

0.05 |

||||

|

-55 |

94 |

YKDD24-326 |

113.40 |

114.15 |

0.75 |

33.40 |

1.52 |

4.19 |

5.71 |

0.23 |

|

|

143.45 |

144.95 |

1.50 |

11.52 |

1.34 |

1.41 |

2.75 |

0.06 |

||||

|

166.30 |

166.80 |

0.50 |

16.75 |

2.93 |

1.99 |

4.92 |

0.08 |

||||

|

-63 |

88 |

YKDD24-328 |

124.80 |

125.67 |

0.87 |

4.15 |

0.10 |

2.49 |

2.59 |

0.02 |

|

|

146.10 |

146.67 |

0.57 |

47.40 |

13.40 |

2.31 |

15.71 |

0.04 |

||||

*Hole YKDD24-317 was lost due to ground conditions and was re-drilled as hole YKDD24-317B.

These exceptionally high grade and lengthy intercepts continue to demonstrate the significant size and grade of the Main Zone mineralization. As previously demonstrated the Main Zone is also significantly enriched in germanium. The germanium results for these intervals are awaited and will be reported when received.

Summary

Cantex’s directors are pleased that drilling at the Massive Sulphide project continues to expand the strike length of the exceptionally high-grade mineralization as reported in Table 1.

Beyond the outstanding silver-lead-zinc grades the mineralization also contains elevated germanium. China has now banned germanium exports to the US resulting in a substantial increase in the germanium price (currently trading at US$2.28 per gram). As China provides the vast majority of the global supply of germanium a western source is needed for the manufacture of a number of modern technologies including computer chips, solar panels, LED lights and night vision goggles. Canadian base metal projects, including North Rackla, have sufficient quantities of germanium to meet the desperate need of the USA.

Sample Preparation

The drill holes reported in this press release were drilled using HQ (63.5mm) diamond drill bits. The core was logged, marked up for sampling and then divided into equal halves using a diamond saw on site. One half of the core was left in the original core box. The other half was sampled and placed into sealed bags. Core samples averaged over 3kg in weight.

The core samples are placed into larger bags closed with security seals prior to being transported to the ISO 9001 certified CF Mineral Research Ltd. laboratory in Kelowna, BC.

At CF Minerals the samples were dried prior to crushing to -10 mesh. The crushed material from a sample was then mixed prior to splitting off 800g. The 800g splits were pulverized to -200 mesh and a 250g split was sent for assay. Quality control procedures included running a barren sand sample through both the crusher and pulveriser between each sample to ensure no inter-sample contamination occurred. Silica blanks were inserted along with certified reference samples. These quality control samples were each inserted approximately every 20 samples.

ALS Chemex in Vancouver assayed the samples using a four-acid digestion with an ICP-MS finish. The 48 element ME-MS61 technique was used to provide a geochemical signature. For samples where lead or zinc values exceeded one percent the Pb-OG62 or Zn-OG62 techniques were used. These have upper limits of 20% lead and 30% zinc respectively. Samples with lead and zinc values over these limits were then analyzed by titration methods Pb-VOL70 and Zn-VOL50. Where silver samples exceeded 100 g/t the Ag-OG62 technique was used which has an upper limit of 1,500 g/t.

The technical information and results reported here have been reviewed by Mr. Chad Ulansky P.Geol., a Qualified Person under National Instrument 43-101, who is responsible for the technical content of this release.

Signed,

Charles Fipke

Dr. Charles Fipke, CM

Chairman

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release. Information set forth in this news release includes forward-looking statements under applicable securities laws. Forward-looking statements are statements that relate to future, not past, events. In this context, forward-looking statements often address expected future business and financial performance, and often contain words such as “anticipate”, “believe”, “plan”, “estimate”, “expect”, and “intend”, statements that an action or event “may”, “might”, “could”, “should”, or “will” be taken or occur, or other similar expressions. All statements, other than statements of historical fact, included herein are forward-looking statements. By their nature, forward-looking statements involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements, or other future events, to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements. Such factors include, among others, risks identified in the management discussion and analysis section of the Company’s interim and most recent annual financial statements or other reports and filings with Canadian securities regulators. Forward looking statements are made based on management’s beliefs, estimates and opinions on the date that statements are made and the respective companies undertake no obligation to update forward-looking statements if these beliefs, estimates and opinions or other circumstances should change, except as required by applicable securities laws. Investors are cautioned against attributing undue certainty to forward-looking statements.

SOURCE Cantex Mine Development Corp.